Term: Thermal expansion

**Prediction and Modeling of Thermal Expansion:**

– Equation of state can predict thermal expansion values at different temperatures and pressures.

– Predicting thermal expansion helps in understanding various state functions.

– Predictive models are crucial for engineering designs affected by thermal expansion.

– Predictions are based on the materials’ coefficient of linear thermal expansion.

– Values of thermal expansion can vary with temperature changes.

– Some materials exhibit negative thermal expansion, known as negative expansion.

– Water and certain alloys show negative thermal expansion within specific temperature ranges.

**Factors Affecting Thermal Expansion:**

– Solid materials maintain their shape during thermal expansion.

– Thermal expansion decreases with increasing bond energy.

– High melting point materials tend to have lower thermal expansion.

– Liquids expand slightly more than solids.

– Glass transition temperature leads to characteristic changes in coefficient of thermal expansion.

**Effects of Thermal Expansion on Density and Material Behavior:**

– Thermal expansion alters the space between particles, changing the substance’s volume.

– Density changes due to thermal expansion impact buoyant forces and convection in fluids.

– Coefficients of thermal expansion help in predicting material behavior under temperature changes.

**Coefficients and Types of Thermal Expansion:**

– Coefficient of thermal expansion measures size change with temperature variation.

– Different types of coefficients exist: volumetric, area, and linear.

– Volumetric coefficient is most relevant for fluids.

– Coefficients help in predicting material behavior under temperature changes.

– Isotropic and anisotropic materials exhibit different expansion characteristics.

**Applications and Examples of Thermal Expansion:**

– Various applications like bimetallic strips, thermometers, and engineering designs utilize thermal expansion.

– Alloys like Invar 36 with minimal linear expansion coefficient find use in aerospace applications.

– Precision engineering always considers the thermal expansion of products.

– Control of thermal expansion is crucial in materials like ceramics and glass to prevent fractures.

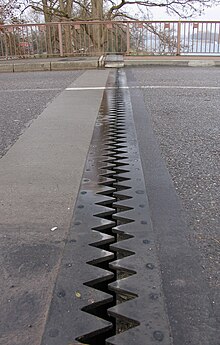

– Large structures like railways and bridges need expansion joints to prevent issues.

This article needs additional citations for verification. (September 2017) |

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions.

Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. Substances which contract with increasing temperature are unusual, and only occur within limited temperature ranges (see examples below).

The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. As energy in particles increases, they start moving faster and faster, weakening the intermolecular forces between them and therefore expanding the substance.