Term: Prestressed concrete

**1. Prestressed Concrete Concepts:**

– Prestressed concrete strengthens against tensile forces

– Tensioning of high-strength tendons improves performance

– Characteristics of high-strength concrete and steel

– Internal stresses are introduced in a planned manner

– Used in high-rise buildings, bridges, and industrial structures

**2. Pre-tensioned Concrete Concepts:**

– Tendons are tensioned before concrete casting

– Strong end-anchorage points are required

– Bond strength between concrete and tendons is critical

– Tendons generally form straight lines between anchorages

– Used for structural beams, floor slabs, and water tanks

**3. Post-tensioned Concrete Concepts:**

– Tendons are tensioned after concrete casting

– Tendons are encapsulated within protective sleeves

– Large forces are required to tension the tendons

– Different anchorage systems are used based on tendon composition

– Tendon encapsulation systems are made from plastic or steel

**4. Bonded and Unbonded Post-tensioning Concepts:**

– Bonded Post-tensioning:

– Tendons are permanently bonded to surrounding concrete

– Grouting protects tendons against corrosion

– Bundling of elements inside a single tendon duct is common

– Improves structural behaviors of the final concrete structure

– Used for efficient tendon installation and grouting processes

– Unbonded Post-tensioning:

– Tendons are not bonded to surrounding concrete

– Tendons are encapsulated within a greased sheath

– Reaction forces from tendon profiling counter loadings

– Ducts/sleeves can be profiled to any desired shape

– Beneficial for countering loadings applied to the structure

**5. Applications and Notable Structures:**

– Applications of Prestressed Concrete:

– Versatile in construction with high-strength steel and modern concrete

– Used in major design codes for various structures like buildings, bridges, dams, and pavements

– Utilized in stadiums, silos, tanks, and other civil structures

– Notable Structures:

– Examples include the Sydney Opera House, CN Tower, and the Gateway Bridge

– Also used in the construction of LNG tanks, nuclear reactor vessels, and blast-containment walls

– Various organizations worldwide promote best practices in prestressed concrete design and construction

This organization groups similar concepts together for a more structured and comprehensive understanding of prestressed concrete technology and its applications.

Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" (compressed) during production, in a manner that strengthens it against tensile forces which will exist when in service.

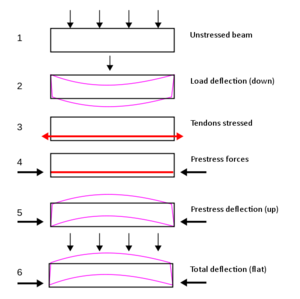

- Non-prestressed beam without load

- Non-prestressed beam with load

- Before concrete solidifies, tendons embedded in concrete are tensioned

- After concrete solidifies, tendons apply compressive stress to concrete

- Prestressed beam without load

- Prestressed beam with load

This compression is produced by the tensioning of high-strength "tendons" located within or adjacent to the concrete and is done to improve the performance of the concrete in service. Tendons may consist of single wires, multi-wire strands or threaded bars that are most commonly made from high-tensile steels, carbon fiber or aramid fiber. The essence of prestressed concrete is that once the initial compression has been applied, the resulting material has the characteristics of high-strength concrete when subject to any subsequent compression forces and of ductile high-strength steel when subject to tension forces. This can result in improved structural capacity and/or serviceability compared with conventionally reinforced concrete in many situations. In a prestressed concrete member, the internal stresses are introduced in a planned manner so that the stresses resulting from the imposed loads are counteracted to the desired degree.

Prestressed concrete is used in a wide range of building and civil structures where its improved performance can allow for longer spans, reduced structural thicknesses, and material savings compared with simple reinforced concrete. Typical applications include high-rise buildings, residential slabs, foundation systems, bridge and dam structures, silos and tanks, industrial pavements and nuclear containment structures.

First used in the late nineteenth century, prestressed concrete has developed beyond pre-tensioning to include post-tensioning, which occurs after the concrete is cast. Tensioning systems may be classed as either monostrand, where each tendon's strand or wire is stressed individually, or multi-strand, where all strands or wires in a tendon are stressed simultaneously. Tendons may be located either within the concrete volume (internal prestressing) or wholly outside of it (external prestressing). While pre-tensioned concrete uses tendons directly bonded to the concrete, post-tensioned concrete can use either bonded or unbonded tendons.