Term: Cement

Types of Cement

– Cement materials can be classified into hydraulic cements and non-hydraulic cements.

– Hydraulic cements require water for setting and hardening, while non-hydraulic cements can set under air.

– Hydraulic cements, such as Portland cement, consist of silicates and oxides.

– The main mineral phases of hydraulic cements are alite, belite, tricalcium aluminate, and brownmillerite.

– Non-hydraulic cement sets as it dries and reacts with carbon dioxide in the air.

– Non-hydraulic cement does not require water for setting and hardening.

– Non-hydraulic cement is resistant to chemical attack after setting.

Chemistry of Cement

– Hydraulic cement hardens through hydration of clinker minerals when water is added.

– The main mineral phases of hydraulic cement are responsible for its mechanical properties.

– The limestone is burned to produce lime in a calcination reaction.

– Lime reacts with silicon dioxide to form dicalcium silicate and tricalcium silicate.

– Lime also reacts with aluminum oxide to form tricalcium aluminate.

– Calcium oxide is obtained by thermal decomposition of calcium carbonate.

– The chemistry of these reactions is still the subject of research.

Ancient Alternatives to Cement

– Bitumen was used by the Babylonians and Assyrians to bind burnt brick or alabaster slabs.

– Ancient Egyptians used sand and burnt gypsum mortar for cementation.

– Ancient Greeks used crushed potsherds as a pozzolan for hydraulic cement.

– Roman engineers used volcanic ash and lime for hydraulic cement.

– Crushed brick or pottery was used as a substitute for pozzolanic ash.

Historical Use of Cement

– Lime was used by the Ancient Greeks and Minoans for cementation.

– The Greeks used volcanic tuff from Thera as a pozzolan.

– Roman engineers used crushed volcanic ash with lime for hydraulic cement.

– The material was called pozzolana and was extracted from Pozzuoli.

– Roman concrete was extensively used in structures like the Pantheon and Baths of Caracalla.

– Hydraulic cement actively used by medieval masons and military engineers in the Middle Ages.

– Structures such as canals, fortresses, harbors, and shipbuilding facilities were constructed.

– Lime mortar and aggregate with brick or stone facing material used in the Eastern Roman Empire and Gothic period.

– German Rhineland utilized hydraulic mortar with local pozzolana deposits.

Development of Cement Techniques

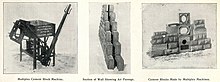

– Tabby, a building material made from oyster shell lime, sand, and whole oyster shells, introduced in the 16th century.

– Concrete formed using tabby.

– French and British engineers formalized technical knowledge for making hydraulic cement in the 18th century.

– John Smeaton’s contribution to cement development for Eddystone Lighthouse construction.

– Parkers Roman cement developed by James Parker in the 1780s.

– Louis Vicat identified the principle of combining chalk and clay for cement production in the 19th century.

– Vicat devised a method for intimate mixture of chalk and clay.

– Burning process used in cement production.

– Roman cement replaced by Portland cement in the 1850s.

– Smeaton’s work on hydraulic cement apparently unknown to Vicat.

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource.

Cements used in construction are usually inorganic, often lime or calcium silicate based, which can be characterized as hydraulic or the less common non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster).

Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble and so are quite durable in water and safe from chemical attack. This allows setting in wet conditions or under water and further protects the hardened material from chemical attack. The chemical process for hydraulic cement was found by ancient Romans who used volcanic ash (pozzolana) with added lime (calcium oxide).

Non-hydraulic cement (less common) does not set in wet conditions or under water. Rather, it sets as it dries and reacts with carbon dioxide in the air. It is resistant to attack by chemicals after setting.

The word "cement" can be traced back to the Ancient Roman term opus caementicium, used to describe masonry resembling modern concrete that was made from crushed rock with burnt lime as binder. The volcanic ash and pulverized brick supplements that were added to the burnt lime, to obtain a hydraulic binder, were later referred to as cementum, cimentum, cäment, and cement. In modern times, organic polymers are sometimes used as cements in concrete.

World production of cement is about 4.4 billion tonnes per year (2021, estimation), of which about half is made in China, followed by India and Vietnam.

The cement production process is responsible for nearly 8% (2018) of global CO2 emissions, which includes heating raw materials in a cement kiln by fuel combustion and resulting release of CO2 stored in the calcium carbonate (calcination process). Its hydrated products, such as concrete, gradually reabsorb substantial amounts of atmospheric CO2 (carbonation process) compensating near 30% of initial CO2 emissions, as estimations suggest.