Term: Concrete saw

Blade choice

– Consider the diamond saw blades’ features and the type of concrete/asphalt being cut

– Take into account the presence of steel bars in reinforced concrete

– Differentiate between pebbles and crushed rocks in concrete stone aggregate

– Account for the curing time of the concrete (long or short)

– Ensure the diamond saw blades are designed to fit the specific concrete and asphalt

Wet or dry cutting

– Diamond saw blades for concrete are usually designed for wet cutting

– Inadequate water during dry cutting can cause the diamond segment or steel core to break

– Dry cutting should be intermittent and shallow to keep the blade cool

– Choose sharper diamond blades for dry cutting if water source is not available

– Dry cutting should be done in several passes to achieve a deep cut

Faster cutting or longer lifespan

– Determine the basic cutting speed of the diamond saw blades

– Select a blade with faster cutting speed or longer lifespan based on the determined speed

– Consider the specific cutting requirements for the task at hand

– Evaluate the trade-off between cutting speed and lifespan

– Choose a blade that meets the desired balance between speed and lifespan

Power output of the concrete saw

– Higher power output requires a higher diamond concentration or a harder bond

– Lower power output requires a lower diamond concentration or a softer bond

– Diamond concentration and bond hardness affect the blade’s sharpness

– Consider the impact on the diamonds when cutting with high power output

– Ensure the blade can achieve the necessary cutting speed based on the saw’s power output

Dust control

– Cutting materials like stones, rocks, sands, and clays can produce airborne dust containing fine respirable crystalline silica (RCS) particles

– RCS particles can cause serious health effects such as lung cancer or silicosis

– Wet cutting with adequate water supply helps control dust

– Diamond saw blades are preferable to abrasive blades for faster cutting with less water

– Local exhaust ventilation (LEV) systems can capture the majority of dust emitted during cutting operations

This article needs additional citations for verification. (December 2009) |

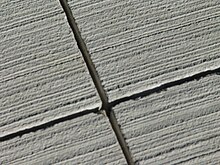

A concrete saw (also known as a consaw, road saw, cut-off saw, slab saw or quick cut) is a power tool used for cutting concrete, masonry, brick, asphalt, tile, and other solid materials. There are many types ranging from small hand-held saws, chop-saw models, and big walk-behind saws or other styles, and it may be powered by gasoline, hydraulic or pneumatic pressure, or an electric motor. The saw blades used on concrete saws are often diamond saw blades to cut concrete, asphalt, stone, etc. Abrasive cut-off wheels can also be used on cut-off saws to cut stone and steel. The significant friction generated in cutting hard substances like concrete usually requires the blades to be cooled to prolong their life and reduce dust.